Core Functions and System Integration of the Tower Box

Definition and Basic Function of a Tower Box

Tower boxes act as control centers for each section of those big circular irrigation systems we see on farms. These durable enclosures contain all the electrical parts needed to manage how the drive motors work, which helps keep the towers moving smoothly even when the ground isn't flat. What makes them different from older passive junction boxes is their ability to actually watch what's happening with the load. If something gets stuck or blocked, these newer models will automatically shut off the motors before any real damage occurs. According to recent industry research from last year, farmers who upgrade to properly set up tower boxes experience about a quarter less alignment problems than those still using simple relay systems. That kind of improvement adds up over time in terms of both maintenance costs and system longevity.

How the Tower Box Integrates with Center Pivot Irrigation System Components

Through standardized communication protocols, the tower box synchronizes with three critical subsystems:

- Drive motors: Modulates power delivery based on real-time torque requirements

- Alignment sensors: Adjusts rotation speed when span angles exceed 2° tolerance

- Central controller: Transmits pressure/voltage data every 5–15 seconds for system-wide diagnostics

This integration enables precise water application while compensating for field elevation changes up to 30% slope gradient.

The Evolution from Mechanical to Digital Tower Box Systems

Most modern equipment has moved away from old fashioned manual switches to those fancy PLCs that can actually check themselves for problems. Take the newest models out there in 2024 for instance they come with IoT features that do something called dynamic load balancing which basically means shifting power around between motors when the voltage drops unexpectedly. Some real world testing showed these new systems are about 35 percent better at keeping things synced up compared to what was available back in the early 2010s. For big farm operations this matters a lot because it lets growers keep their water distribution pretty consistent across all those towers with only about 1.5% variation in speed. That kind of precision makes a huge difference when trying to get even coverage over thousands of acres.

Electrical and Mechanical Control Mechanisms in the Tower Box

Power Distribution and Motor Control in the Tower Box

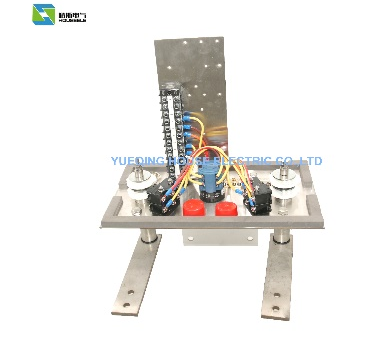

At the heart of center pivot irrigation systems sits what's called a tower box, basically serving as the main electrical connection point. This component sends power out to all those drive motors responsible for moving each individual tower along the field. These days most advanced setups incorporate things like solid state relays alongside programmable logic controllers or PLCs for short. They work together to manage how much force gets applied to each motor and how fast they spin, which helps keep everything moving smoothly across different types of ground conditions. Looking at recent developments in motor control tech, there have been some pretty impressive improvements reported lately. When farmers start pairing dynamic load monitoring techniques with variable frequency drives known as VFDs, they're seeing around a 12 to maybe even 18 percent boost in overall system efficiency according to field tests conducted over several growing seasons.

Relay Operations and Circuit Protection Mechanisms

The relays inside those tower boxes act like emergency cutoff switches that stop the power when there's too much load or if something goes wrong with the grounding. For motor protection against long term overcurrent situations, thermal magnetic circuit breakers along with resettable fuses are essential equipment. According to research published in the Agricultural Engineering Journal back in 2023, these kinds of issues actually cause around 34 percent of all problems in irrigation systems. Beyond that basic protection, having redundant grounding points plus good quality surge suppressors makes a big difference too. These extra measures help keep expensive electronic components safe from sudden voltage jumps that can come from lightning strikes or just regular fluctuations in the electrical grid itself.

Integration with Drive Systems for Tower Movement

The tower box synchronizes mechanical and electrical components by converting control signals into physical motion. Encoder feedback from gearboxes enables real-time speed adjustments, while limit switches prevent overtravel. This integration minimizes lateral drift, maintaining pivot alignment within 2° of the central axis even on sloped terrain.

Monitoring Load and Preventing Overcurrent Failures

Current transformers (CTs) continuously measure motor amperage, triggering automated shutdowns if loads exceed safe thresholds. Advanced systems use predictive algorithms to detect bearing wear or misalignment, reducing unplanned downtime by 41% compared to traditional setups (Farm Energy Efficiency Report, 2024).

Communication, Synchronization, and Real-Time Signal Processing

Data Transmission Between Tower Boxes and the Central Pivot Controller

The tower box serves basically as the main communication point, sending back all sorts of operational info from each pivot tower to the central control panel. These days most modern setups rely on either CAN bus protocols or RS-485 serial connections to get important stuff like motor loads, position readings, and any fault alerts across every 1 to 2 seconds. Having this constant stream of information allows operators to tweak things like how fast water flows and where it goes from one central location. At the same time, the tower boxes still keep their own brains so they can make quick decisions based on what's happening right there on site without waiting for instructions from above.

Use of Radio Signals and Wired Communication Networks

Hybrid networks ensure reliability across expansive fields:

- Radio systems (900 MHz or 2.4 GHz bands) provide wireless connectivity between towers, tolerating signal attenuation over 0.5-mile spans

-

Wired backbone networks using armored fiber-optic cables deliver interference-resistant communication for high-priority commands

Field tests show wired links reduce latency by 40% compared to radio-only configurations (Irrigation Tech Journal 2023).

Error Detection and Fault Reporting in Real Time

Modern tower box systems now include CRC technology for spotting damaged data packets, and real world tests show these systems typically have error rates under 0.01%. If something goes wrong, like when motors get overloaded or components start drifting out of alignment, the system knows what to do first according to IEEE 1646 guidelines. Warnings travel down from problem towers to the main control center pretty quickly too, usually taking around 300 milliseconds or so for the whole chain reaction to happen.

Synchronization of Tower Movement Across the Pivot Span

Precision timing protocols synchronize tower speeds within ±2% variance, preventing structural stress during directional changes. A 2024 study demonstrated that time-sensitive networking (TSN) techniques improved pivot alignment accuracy by 28% compared to traditional clock synchronization methods, enabling tighter radius turns without tower collisions.

Sensor Integration and Adaptive Response in Tower Box Operation

Monitoring Terrain Slope and Adjusting Tower Speed

Today's tower boxes come equipped with IMUs and tilt sensors that can pick up even pretty steep terrain changes around 15 degrees give or take about 7.5 degrees from flat ground. What these smart systems do is actually change the speed of the tower motors using something called PWM technology. This helps cut down on wheel slippage quite a bit - somewhere around 42 percent less than what happens with those old fixed speed systems according to some research done last year in the field of irrigation efficiency. Looking at another angle, there was this report from the DIAC back in 2023 talking about how combining multiple sensor inputs in these towers makes water spread out much more evenly across hillsides. They found that water gets distributed about 31% better when using these advanced systems on sloped farmland.

Response to Obstruction Detection and Stall Conditions

Built-in torque sensors trigger automated responses when obstructions increase drive system resistance beyond preset thresholds (typically 110–130% of normal load). The tower box executes a 3-stage protocol:

- Reverse movement (2–3 ft)

- Torque re-evaluation

-

Full shutdown if resistance persists

This cascade prevents gearbox failures responsible for 23% of pivot downtime (Pivot Maintenance Consortium 2023 data).

Integration with GPS and Telemetry for Precision Control

Tower boxes now interface with RTK-GPS receivers (±2 cm accuracy) to enable:

| Feature | Impact |

|---|---|

| Speed synchronization | Reduces lateral alignment errors by 58% |

| Sector-specific RPMs | Optimizes energy use (19% avg. savings) |

| Geofencing | Prevents boundary overruns |

| Telemetry systems transmit shaft rotation data every 30 seconds to central controllers, enabling real-time correction of tower movement deviations >5% from programmed paths. |

Maintenance, Diagnostics, and Future Advancements in Tower Box Technology

Common Failure Modes and Diagnostic Indicators

Tower boxes often fail due to moisture ingress (35% of field service calls), relay contact corrosion, or overcurrent sensor drift. Advanced models now use color-coded LED diagnostics—solid red for power supply issues, flashing amber for communication errors—reducing diagnostic time by 50% compared to traditional multimeter checks.

Troubleshooting Procedures and Preventive Maintenance Best Practices

Field technicians follow hierarchical protocols:

- Verify incoming voltage stability (±10% of 480V AC nominal)

- Test ground continuity (<1Ω resistance)

-

Inspect surge protection modules (replace at 85% capacitance loss)

Scheduled maintenance every 1,500 irrigation hours extends component lifespan by 3–4 seasons according to USDA irrigation efficiency studies.

Smart Tower Boxes: IoT Integration and Remote Monitoring

Modern systems transmit operational data through encrypted LoRaWAN networks, enabling farmers to monitor tower alignment precision within ±0.25° via smartphone. Predictive maintenance algorithms analyze current signatures, flagging motor bearing wear 60–80 hours before failure.

Energy Efficiency and Solar-Powered Innovations

Recent designs integrate Maximum Power Point Tracking (MPPT) solar chargers, reducing grid dependency by 40% in daylight operations. Night-mode algorithms optimize motor pulse sequences, cutting energy consumption by 18% without compromising watering uniformity.

Proprietary vs. Open-Source Communication Protocols: Industry Debate

While 72% of installed systems use MODBUS RTU for compatibility, emerging open-source protocols like AgriCAN enable cross-brand data sharing. Security audits show encrypted AES-256 protocols reduce attack surface by 90% compared to legacy systems.

Frequently Asked Questions

What are the main functions of a tower box in center pivot irrigation?

A tower box serves as the control center, managing drive motor functions, alignment with sensors, and communication with the central controller, ensuring smooth operation and system-wide diagnostics.

How does the tower box contribute to irrigation efficiency?

By integrating with various subsystems, a tower box allows for precise water application and dynamic load balancing, reducing inefficiencies and ensuring consistent irrigation across vast fields.

What advancements have been made in tower box technology?

Recent models include IoT integration, dynamic load balancing, real-time signal processing, and solar-powered innovations, significantly boosting efficiency and reliability.

How do tower boxes handle communication?

Tower boxes utilize both wired and wireless systems like CAN bus protocols, RS-485 serial connections, and hybrid networks to transmit operational data, ensuring seamless information flow across extensive fields.

What maintenance practices are recommended for tower boxes?

Regular maintenance every 1,500 irrigation hours, voltage stability verification, ground continuity tests, and surge protection inspections are crucial to extending component lifespan and preventing issues.

Table of Contents

- Core Functions and System Integration of the Tower Box

- Electrical and Mechanical Control Mechanisms in the Tower Box

- Power Distribution and Motor Control in the Tower Box

- Relay Operations and Circuit Protection Mechanisms

- Integration with Drive Systems for Tower Movement

- Monitoring Load and Preventing Overcurrent Failures

- Communication, Synchronization, and Real-Time Signal Processing

- Sensor Integration and Adaptive Response in Tower Box Operation

- Maintenance, Diagnostics, and Future Advancements in Tower Box Technology

- Frequently Asked Questions