Core Irrigation Control Capabilities of Modern Tower Boxes

Scheduling, multi-zone valve control, and dynamic water budgeting

Tower box systems today allow for much finer control over irrigation schedules across different areas, making adjustments to water distribution based on what's happening in the environment right now. These systems use sophisticated math behind the scenes to look at things like how dry the soil actually is, how fast plants are losing water through transpiration, and what kind of crops are growing there. According to numbers from the Irrigation Association released last year, these smart systems can cut down on wasted water somewhere between 15% and 30% when compared to old fashioned timers that just run on fixed schedules regardless of conditions. What makes these systems really effective is their valve control components which handle each pressure compensated zone separately. This means hills and valleys get exactly what they need without one area getting too wet while another remains parched.

Real-time diagnostics and fault detection for irrigation uptime assurance

Keeping track of electrical parameters like voltage, current and phase helps spot problems in the field right away when things go wrong with wires breaking, solenoids failing or motors getting overloaded. When something happens, automated systems send warnings to operators about serious problems including when pressure falls below 15 PSI or motors stop working completely, usually within just half a minute. According to research done on actual installations, these monitoring capabilities cut down downtime by around half because technicians can fix specific issues before bigger system failures start happening across multiple components.

Integration with Industrial and Smart Irrigation Ecosystems

Seamless PLC, SCADA, and cloud platform compatibility

Tower boxes today offer pretty good compatibility with industrial systems because they work right out of the box with PLCs and SCADA setups. Farmers can monitor all their irrigation valves, pressure sensors, and flow meters from one central location even on big farms stretching across hundreds of acres. When these boxes link up with cloud platforms similar to what smart irrigation controllers use, they keep everyone's schedules in sync no matter where equipment is located. What makes this setup really useful is that if there's ever a network problem somewhere, the system automatically switches over without losing control of the valves locally.

Modbus RTU, LoRaWAN, and MQTT support for scalable tower box networks

When scaling systems, strong communication is essential, and tower boxes handle this challenge with their three layer approach. They work with older equipment using Modbus RTU, send signals over long distances with LoRaWAN technology, and communicate with clouds through MQTT. What makes this setup really powerful is how it creates network structures where many devices can talk back to main hubs without needing wires everywhere. Think about agricultural settings where soil moisture sensors transmit readings wirelessly to these towers, which then activate valves controlled by Modbus while keeping records through MQTT services. Field tests in orchards showed these wireless setups got deployed around 40 percent quicker compared to traditional wired methods. Plus, everything stays secure thanks to encryption throughout the system, making them ideal even when powered by solar panels in hard to reach locations.

Field-Ready Reliability: Electrical Design, Environmental Protection, and Power Flexibility

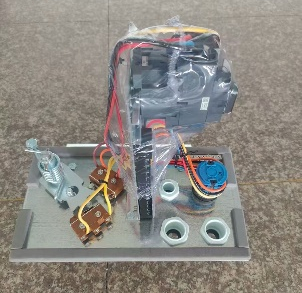

IP67-rated enclosures, 24VAC solenoid drivers, and surge-protected I/O

Tower boxes built for industrial use come with enclosures rated IP67, meaning they keep out dust completely and can handle being submerged in water up to one meter deep for half an hour. This kind of protection matters a lot at irrigation sites prone to flooding. The units also have 24VAC solenoid drivers inside that help keep the voltage steady throughout the entire network of valves. Without this stability, pressure would drop when multiple zones activate at once, causing problems in the system. All input/output ports are protected against surges from lightning or sudden voltage changes something that regularly brings down equipment in farms and greenhouses. Made with materials resistant to chemicals, these boxes last about 40% longer than standard models in places where fertilizer runoff eats away at metal components. Farmers appreciate this durability because it means fewer breakdowns right when crops need consistent watering most.

Solar-compatible DC vs. AC operation: performance trade-offs in off-grid deployments

When setting up off grid tower boxes with solar power, engineers need to make tough calls about efficiency tradeoffs. Direct current systems take power straight from the panels and batteries with around 90 to 95 percent efficiency, which works great in remote areas. The catch? These systems can't handle multiple valves opening at once because they hit their current limits pretty quick. Alternating current setups come with inverters that let them manage bigger surges when several valves start up together, but there's a price to pay here too. Those inverters eat up about 10 to 15 percent of the energy during conversion, so folks end up needing much bigger solar arrays. Looking at actual field tests in desert conditions tells another story though. For smaller installations covering just a few acres, going with DC cuts down on solar equipment costs by roughly a quarter. But when dealing with bigger complexes that have more than eight valves, most installers still go with AC since those initial power spikes require significantly more wattage at startup.

Adaptive Control Through Sensor Fusion and Real-Time Synchronization

Soil moisture, ET, and canopy temperature integration for precision scheduling

The latest tower box systems are changing how farmers manage their irrigation setups. These devices combine information about soil moisture levels, evapotranspiration rates (ET), and what's happening with canopy temperatures across fields. When all these data points come together, they allow for smarter watering schedules that actually match what's going on in the field right now. No more guessing games during those hot summer days when plants really need water, nor wasting resources after it rains. The system looks at changes in canopy temps throughout the day to spot when plants start getting stressed out long before anyone notices anything wrong visually. Farmers who tested this tech reported seeing around 22% better yields from crops sensitive to water fluctuations such as lettuce, simply because they could react faster to changing conditions in their fields.

Time-synchronized PWM across distributed tower boxes — lessons from UC Davis almond trials

When it comes to irrigation systems spread out over big areas, time synced pulse width modulation (PWM) makes things work together better than ever before. Researchers at UC Davis looked at almond farms and saw something interesting happen with these special tower boxes that can time their actions down to the microsecond. These devices basically stop those annoying pressure changes that usually plague large orchards. According to what they found, using this synchronized approach cut down on energy usage by about 18 percent. Plus, water gets distributed much more evenly throughout the fields, hitting around 92% efficiency mark. What's really impressive is how each tower box stays connected all the time with delays under 50 milliseconds. That means valves open just right when there's high demand for water. The system also avoids those sudden jolts in water pressure that happen when too many zones turn on at once. Farmers report seeing about 15% fewer clogged emitters and no more dry patches showing up in tricky landscapes. For growers with long term crops like almonds or grapes, this tech becomes essential since healthy roots need steady moisture levels day after day.

FAQ Section

What are the benefits of using tower box systems in irrigation?

Tower box systems provide precise control over irrigation schedules, allowing for efficient water distribution across different areas based on environmental conditions. They can reduce water waste by 15-30% compared to traditional timers.

How do tower boxes ensure irrigation uptime?

Tower boxes monitor electrical parameters and send warnings to operators when issues arise, helping to spot problems immediately and reduce downtime by fixing issues before bigger failures occur.

How do tower boxes integrate with industrial systems?

Tower boxes offer compatibility with PLCs, SCADA, and cloud platforms, allowing farmers to monitor irrigation parameters from a central location and maintain schedule synchronization even during network disruptions.

What types of communication do tower boxes support?

Tower boxes support Modbus RTU, LoRaWAN, and MQTT, providing scalable network structures where devices can communicate back to main hubs wirelessly, facilitating faster deployment compared to traditional wired methods.

How do tower boxes adapt to off-grid deployments?

Tower boxes can operate in off-grid setups using solar power, with DC systems offering high efficiency, though limited by valve operations, while AC setups manage larger surges but require bigger solar arrays.