Understanding the Role of Couplers in Irrigation System Performance

How couplers enable modular and scalable irrigation networks

Couplers play a key role in building irrigation setups that can grow and change as farming requirements evolve over time. Farmers find these standardized connections really helpful when adding new sections to their system because they cut down on setup work. Some studies from last year showed installation times drop around two thirds when using couplers instead of welding everything together. The real advantage comes from being able to upgrade parts of the system bit by bit as needed during planting seasons or when new tech becomes available on the market. Most growers appreciate this flexibility since it saves money while still keeping water distribution efficient across different crops.

The function of couplers in maintaining system integrity and flow continuity

Properly matched couplers ensure smooth water flow by minimizing turbulence and pressure drops across pipe junctions. Their sealing mechanisms prevent leaks that can waste up to 14,000 liters/acre annually in drip systems (FAO 2022), preserving water efficiency and ensuring uniform distribution across fields.

Common failures due to improper coupler use in drip irrigation setups

Mismatched or poorly selected couplers contribute to 37% of premature drip line failures, according to a 2024 study of 120 farms. Rigid couplers used with flexible polyethylene tubing accelerate wear, while undersized barbed fittings in high-pressure areas often dislodge, leading to flooding and soil erosion.

Growing demand for quick-connect couplers in smart irrigation systems

Quick-connect couplers now feature in 58% of new commercial installations due to their seamless integration with IoT sensors and automated zone controls. These tool-free connections allow rapid reconfiguration for precision fertigation and maintain performance at pressures up to 125 PSI, supporting variable-rate irrigation strategies.

Aligning coupler functionality with overall irrigation system design goals

Effective coupler selection balances four key priorities: leak resistance (minimum 90 PSI rating), compatibility with agrochemicals, UV stability for outdoor use, and installation speed (under 90 seconds per connection). When aligned with system design, this approach reduces maintenance costs by 32% over five years while enhancing water conservation.

Matching Coupler Size and Type to Irrigation Pipe Specifications

Measuring Pipe Outside Diameter for Accurate Coupler Fit

Digital calipers are essential when measuring a pipe's outer diameter at several spots along its length since manufacturing differences can create variations. Industry reports from 2025 highlighted problems where even small mismatches matter - we saw cases where a mere 1.125 mm space between a 17 mm connector and what should have been a matching 15.875 mm pipe allowed dirt to get inside, costing farmers nearly thirty grand in lost crops. When working with rigid PVC pipes, it makes sense to take measurements at both ends plus somewhere in the middle. Flexible polyethylene tubes require closer attention though. Best practice suggests checking the size every thirty centimeters or so to spot any irregularities before they become bigger issues down the line.

Step-by-Step Guide to Selecting Compatible Couplers Based on Pipe Size

- Verify OD consistency: Accept no more than 0.5mm variation in pipe diameter

- Confirm pressure requirements: Choose couplers rated at least 20% above maximum system pressure (e.g., 60 PSI couplers for 50 PSI systems)

- Test thermal expansion: Allow a 3–5% length gap for materials exposed to temperatures above 95°F

Nominal vs. Actual Pipe Diameter: Clearing Up Common Misconceptions

| Nominal Size | Typical Actual OD | Common Mistake | Ideal Coupler ID |

|---|---|---|---|

| 1/2" PVC | 0.840" | Using 0.75" | 0.845"-0.855" |

| 3/4" PE | 1.050" | Choosing 1" | 1.055"-1.065" |

| 25mm HDPE | 1.181" | Selecting 1" | 30mm (1.181") |

Misinterpreting nominal labels causes 65% of leaks in field systems, according to Agricultural Water Management (2023).

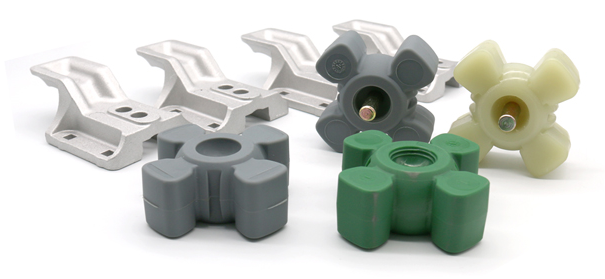

Barbed vs. Compression Couplers for Flexible Tubing Applications

Barbed couplers suit low-pressure drip lines (<15 PSI), relying on friction to secure flexible tubing. Compression couplers are better for medium-pressure systems (15–50 PSI), using rubber seals that tighten during installation. Under vibration stress, compression models maintain 92% flow integrity compared to 78% for barbed types in field tests.

Threaded Couplers for Rigid Pipes: NPT vs. BSP Standards

In high-pressure systems (>50 PSI), threaded couplers prevent blowouts. Use National Pipe Thread (NPT) tapered fittings in North America and British Standard Pipe (BSP) parallel threads internationally. Cross-threading these standards reduces joint strength by 40%, so always verify thread pitch with a gauge before assembly.

Selecting Couplers That Match PVC, Polyethylene, or Metal Pipe Materials

Getting the right coupler material for different pipe types matters a lot when it comes to making sure things last and keeping those pesky leaks at bay. PVC pipes need couplers that expand and contract at about the same rate as the pipe itself around 0.065 mm per meter per degree Celsius for Schedule 40 pipes specifically. This helps keep joints intact even when temperatures go up and down. When working with polyethylene systems, flexible barbed couplers work best because they can handle some movement without cracking. Just remember to keep flow rates under 2.5 gallons per minute if we're talking about drip irrigation setups. Metal pipes like galvanized steel call for brass couplers that include dielectric isolation features. These help stop galvanic corrosion which actually causes about 37 percent of all chemical leaks in metal piping systems according to a study published by Agricultural Engineers back in 2022.

| Pipe Material | Compatible Coupler | Key Consideration |

|---|---|---|

| PVC | PVC solvent weld | Matching schedule rating |

| Polyethylene | Barbed plastic | Flexibility index â¥8.5 |

| Metal | Brass threaded | Dielectric isolation |

Plastic vs. Brass Couplers in High-Pressure Irrigation Systems: Performance Comparison

Plastic couplers are still king in most homes, making up around 72% of what people install according to Irrigation Association data from last year. But when pressure gets serious, brass really shines once we hit over 80 psi. Tests show nylon parts start to warp about 18 times out of 100 at 100 psi after just 500 cycles. Brass on the other hand holds together even under 150 psi conditions for extended periods. There's a catch though. Brass does cost roughly 30 to 40 percent more than alternatives, plus it needs special insulation whenever connected to different types of metal. Looking at sustainability factors for pressures above 100 psi, many professionals now recommend UV stabilized ABS couplers with stainless steel inserts. These hybrid solutions keep the budget friendly aspect of plastic while adding that extra strength typically found in metal components.

Impact of Water Quality and Chemicals on Coupler Material Degradation

Water chemistry significantly affects coupler lifespan. Acidic well water (pH <6.5) erodes brass at 0.12mm/year, while fertilizer-laden fluids accelerate plasticizer loss in PVC by 27% (National Irrigation Research Center 2022). To mitigate degradation:

- Use NSF-61 certified couplers in potable water systems

- Match EPDM rubber gaskets to specific chemical exposure profiles

- Install sacrificial anode rods at metal-coupler junctions

In reclaimed water systems, cross-linked polyethylene (PEX) couplers with over 50% antioxidant additives last up to 14 yearsânearly double the 8-year average of standard PVC under continuous chemical exposure.

Evaluating Pressure, UV Resistance, and Environmental Durability

How Pipeline Working Pressure Affects Coupler Selection and Longevity

Couplers must endure sustained operating pressures and transient spikes. Plastic variants fail 23% more frequently than brass under cyclical stress above 60 PSI (Irrigation Materials Journal 2023). Always select couplers rated for at least 1.5 times the systemâs maximum pressure to account for surges during pump startup.

UV Resistance in Outdoor Installations: Comparing Lifespan of Plastic Couplers

Unstabilized polypropylene couplers degrade 40% faster than UV-resistant versions, developing surface cracks within 3â5 years in high-sunlight regions. For permanent outdoor use, choose couplers with carbon-black additives or acrylic coatings that reflect 98% of UV radiation, extending service life beyond a decade.

Indoor, Outdoor, and Underground Installation Considerations

| Environment | Primary Stressors | Ideal Coupler Type |

|---|---|---|

| Outdoor | UV, temperature swings (-30°F to 120°F) | UV-stabilized ABS with stainless steel clamps |

| Underground | Soil acidity, root intrusion | Chemically inert PVC with compression seals |

| Greenhouse | High humidity, fertilizer exposure | Brass with epoxy coating |

Field Study Data on Coupler Failure Rates Under Environmental Stressors

A 2022 agricultural study tracking 12,000 couplers revealed:

- 62% of failures occurred in UV-exposed zones using plastic couplers rated only for indoor use

- Underground brass couplers maintained 89% reliability after 8 years versus 54% for uncoated variants

- Systems experiencing daily pressure swings exceeding 25 PSI saw coupler failure rates triple compared to stable-pressure setups

Final Checklist for Optimal Coupler Selection and System Integration

Comprehensive checklist for selecting the right coupler by material, size, and system type

Before installation, confirm:

- Material compatibility with existing pipes (PVC, LDPE, or metal)

- Exact pipe outer diameter (measured, not nominal)

- Required coupling mechanism (compression, barbed, or threaded)

- Maximum system pressure rating (reinforced couplers needed above 100 PSI)

- UV resistance for above-ground exposure

Match these criteria to your irrigation methodâdrip systems need leak-proof seals, while pivot systems rely on high-pressure brass couplers for durability.

Water pressure and flow rate thresholds for reliable coupler performance

Regular PVC couplers usually give way somewhere around 120 to 150 pounds per square inch, but those reinforced brass ones can handle well past 200 PSI. When dealing with flow rates exceeding 15 gallons per minute, going for wide bore couplers makes sense because they cut down on turbulence and maintain better pressure throughout the system. Recent research from last year found that about one third of all flow problems in commercial settings were actually caused by couplers that just weren't the right size for the job. Before putting any setup into real operation, it's wise practice to run pressure tests at least 50% higher than what's normally expected. This gives a safety margin and helps catch potential issues early on.

FAQ

What is the main function of couplers in irrigation systems?

Couplers are essential for connecting various parts of an irrigation system, allowing for modularity and scalability as agricultural requirements evolve. They enable efficient upgrades and expansions, reduce installment times, and ensure smooth water flow and integrity.

Why is it important to select the correct coupler size and type?

Correct coupler size and type are crucial for preventing leaks and ensuring system integrity. Mismatched or poorly chosen couplers can lead to premature failures, increased maintenance costs, and inefficient water distribution.

How do couplers affect system maintenance and costs?

Choosing suitable couplers based on the system’s requirements can significantly reduce maintenance costs over time. Proper couplers enhance system durability, prevent leaks, and optimize water conservation, thus offering long-term cost savings.

What materials are couplers compatible with?

Couplers must match the materials of the pipes they connect, such as PVC, polyethylene, or metal, to ensure compatibility and durability. Using the right material helps prevent chemical corrosion and system failures.

How does water quality affect coupler material?

Water chemistry, including acidity and chemical exposure, can degrade coupler materials. Specific couplers and gaskets are recommended based on their chemical resistance to prolong lifespan and maintain performance standards.

Table of Contents

-

Understanding the Role of Couplers in Irrigation System Performance

- How couplers enable modular and scalable irrigation networks

- The function of couplers in maintaining system integrity and flow continuity

- Common failures due to improper coupler use in drip irrigation setups

- Growing demand for quick-connect couplers in smart irrigation systems

- Aligning coupler functionality with overall irrigation system design goals

-

Matching Coupler Size and Type to Irrigation Pipe Specifications

- Measuring Pipe Outside Diameter for Accurate Coupler Fit

- Step-by-Step Guide to Selecting Compatible Couplers Based on Pipe Size

- Nominal vs. Actual Pipe Diameter: Clearing Up Common Misconceptions

- Barbed vs. Compression Couplers for Flexible Tubing Applications

- Threaded Couplers for Rigid Pipes: NPT vs. BSP Standards

- Selecting Couplers That Match PVC, Polyethylene, or Metal Pipe Materials

- Plastic vs. Brass Couplers in High-Pressure Irrigation Systems: Performance Comparison

- Impact of Water Quality and Chemicals on Coupler Material Degradation

- Evaluating Pressure, UV Resistance, and Environmental Durability

- Final Checklist for Optimal Coupler Selection and System Integration

- FAQ