Daqiao Industrial Zone,Beibaixiang Town,Yueqing city,Zhejiang Province. 86-15356512777 [email protected]

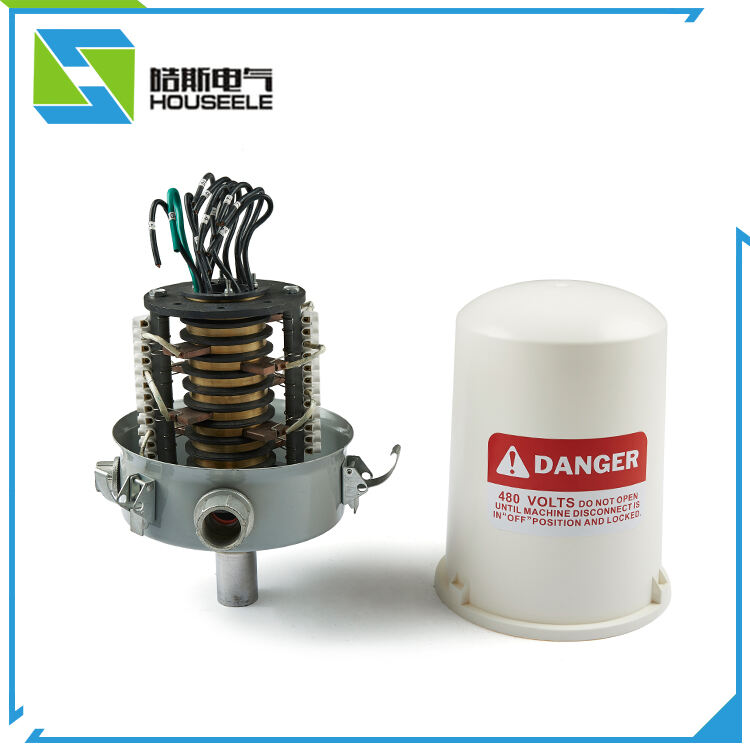

The 11 rings collector ring is a specialized electrical component designed to transmit electrical power and signals between a stationary and a rotating part of a machine. As the name implies, it features 11 individual rings, each insulated from one another, allowing for the simultaneous transfer of multiple electrical circuits. This configuration is particularly useful in applications where a high number of independent electrical connections need to be maintained during rotation, such as in complex industrial machinery or advanced automation systems. Constructed with precision, the 11 rings collector ring typically consists of high - quality conductive materials for the rings themselves, often copper or brass, which offer excellent electrical conductivity and durability. The insulation between the rings is made from robust materials like epoxy resin, ceramic, or high - temperature plastics, ensuring reliable isolation and preventing short - circuits. The rings are mounted on a sturdy hub or shaft, which is designed to withstand the mechanical stresses and vibrations associated with rotational motion. In operation, the 11 rings collector ring works by maintaining continuous electrical contact with stationary brushes. These brushes, usually made of carbon or metal - graphite composites, press against the rotating rings, creating a low - resistance electrical path. As the machine rotates, the electrical current or signals flow from the stationary source through the brushes to the rings and then to the rotating part of the machine. This seamless transfer enables the operation of various electrical components on the rotating assembly, such as motors, sensors, or actuators. Maintenance of the 11 rings collector ring is crucial for its long - term performance. Regular inspection is necessary to check for wear and tear on the rings and brushes. The brushes may need to be replaced periodically as they gradually wear down due to friction. Additionally, ensuring proper lubrication of the moving parts and keeping the collector ring clean from dust, debris, and contaminants helps prevent electrical issues and extends the lifespan of the component. With its ability to handle multiple electrical circuits simultaneously, the 11 rings collector ring provides a reliable and efficient solution for power and signal transmission in rotating machinery.

Copyright © 2025 by Yueqing House Electric Co.,Ltd - Privacy policy